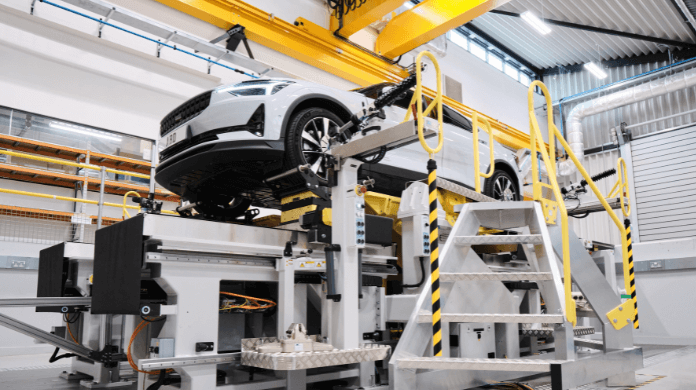

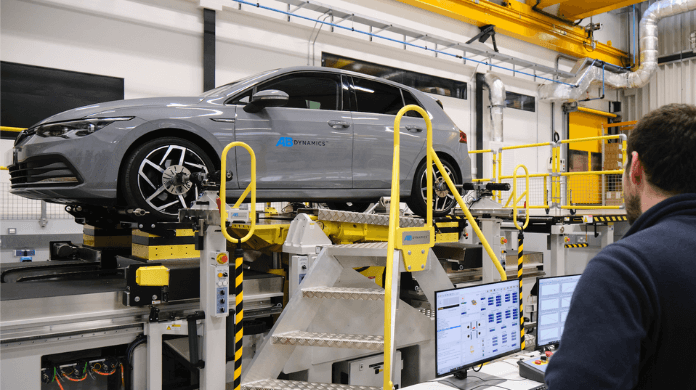

ClearTrack is the latest addition to AB Dynamics’ Automated Driverless Testing solution. It is a LiDAR-based object detection system designed to enhance driverless vehicle testing by identifying and avoiding unexpected obstacles on the proving ground. We sat down with ClearTrack project leader and Senior Embedded and Control Software Engineer at AB Dynamics, Jonathan Barry, to learn more about how the system works, what problems it solves, and why it matters to automotive test teams.

Q: Let’s start from the top, what exactly is ClearTrack?

JB: ClearTrack is an object detection system that can be fitted to AB Dynamics driverless test vehicles to enhance their safety case. In simple terms, its job is to identify potentially hazardous obstacles, such as wildlife, debris or cars, that might appear on the track during driverless testing. If something is detected, and judged to be a collision risk, the system will automatically trigger the vehicle to stop.

Q: Why is this an important addition to the driverless solution?

JB: Driverless testing is becoming increasingly common in the industry. Removing the human driver from long, repetitive or potentially harmful tests eliminates fatigue-related variability and reduces risk. It also enables teams to run multiple vehicles simultaneously from one base station to significantly increase efficiency.

Our customers are experiencing these benefits and are now looking to rapidly scale its use. Running a large fleet would significantly increase the operator's workload and it would be difficult to manage them all safely. And that’s where object detection comes in. It detects and classifies obstacles in real-time and intervenes if there’s a genuine collision risk. This makes it much easier to monitor the test fleet and adds an extra layer of safety to the operation. Ultimately, it allows test teams to deploy driverless systems more confidently and at greater scale, whilst also protecting expensive prototype vehicles and reducing downtime.

Q: How does ClearTrack work?

JB: The system uses a solid-state, ultra-long-range LiDAR sensor mounted on the vehicle roof. This provides tens of thousands of reflected data points every second. ClearTrack filters and processes that data to determine the shape, position, and direction of any obstacle in the vehicle's path.

What’s unique is how it integrates with our robot control system. Because we command the future path the vehicle will follow, we can make more informed decisions about whether an object is actually in the way. This reduces unnecessary stops to keep test programmes on time.

Q: Are there any other ways it minimises false positives?

JB: ClearTrack can be finely tuned to filter out obstacles that don’t pose a genuine risk of damage to the vehicle, such as low lying or sparse foliage. This can be done using ClearTrack’s configurable settings, which also allow the user to control the sensitivity of the system. The object height filters are particularly useful if you need to pass through tunnels or under bridges on your track. This all helps keep testing efficient without compromising safety.

Q: What risks do driverless test vehicles face on proving grounds and how does ClearTrack mitigate them?

JB: Even in well-managed proving grounds, things like fallen branches or wildlife can unexpectedly end up on the track. For example, we’ve had cases of wild deer or even turkeys wandering into test areas.

When you are dealing with rare and expensive prototype vehicles, the last thing you want is to bump into a local deer. Even a relatively small collision can have a big impact in terms of time lost. You could try to solve this with fencing or walls, but that gets extremely costly, especially if you’ve got large facilities that need to be managed and maintained; they are also extremely good at keeping animals trapped inside the fenced area!

Q: What were the toughest technical challenges in developing it?

JB: One of the key challenges has been ensuring the system can reliably filter out features of the test track, such as harsh durability surfaces, to avoid false positive detections, whilst also still being sensitive enough to detect small hazardous obstacles. To overcome this, we’ve drawn on our extensive experience of automating driverless testing and supplemented this with real-world testing on the type of proving grounds our customers use.

Q: What kinds of vehicles and test cycles can ClearTrack be used with?

JB: Pretty much anything. The system uses commercially available roof-bar mounts, so installation is quick and simple. It’s designed to work at speeds up to 130 km/h, which meets key requirements for OEM testing, and it’s built to cope with high-vibration conditions too. So, whether you are carrying out long mileage accumulation tests or tough durability tests, ClearTrack is capable of handling it.

Q: What’s next for ClearTrack?

JB: We’re always looking at ways to improve system performance and make it even more adaptable. Right now, the focus is on deploying it to customers and collecting feedback from real-world use. We have integrated a new feature that saves the last two minutes of data if there is an issue. This is sent back to us at AB Dynamics and used to debug and improve the system. That feedback loop is key to making sure the system continues to evolve in line with how test facilities are operating in practice.

Key takeaways:

- ClearTrack is an integrated object detection system that identifies and avoids hazardous obstacles during driverless vehicle testing, enhancing safety and reducing risk.

- It uses a long-range solid-state LiDAR sensor and seamlessly connects to AB Dynamics’ robot control systems for real-time decision-making.

- Designed for fast deployment, ClearTrack mounts to almost any vehicle using standard roof bars and supports testing at speeds up to 130 km/h.

- It helps avoid expensive damage and downtime by detecting genuine obstacles while ignoring minor, non-threatening debris.

- The system enables more efficient test operations, allowing operators to safely manage more vehicles across wider test areas with reduced workload.

For more information on ClearTrack, click here or watch our latest video.