In part one of this blog series, the benefits of using objective test data for the development of complex hybrid braking systems were introduced. In this second part, Allan Johnstone, Principal Project Engineer at AB Dynamics uses a working example to detail the methodology.

When the regenerative brake system on an electrified vehicle reaches its limit of deceleration the mechanical foundation brake needs to be blended in to make up the shortfall. Typically, this happens at a deceleration rate of >3m/s2 or when the vehicle’s speed approaches 0 km/h because the braking torque from the electric motor drops off. In these scenarios, where the systems are being blended, brake feel is critical because often the driver can experience varying levels of deceleration for a given demand. This can be disconcerting and result in the driver needing to modulate the brake pedal input, which can exasperate the issue.

Brake feel analysis of a hybrid vehicle using brake robots

For the first time, this type of situation can now be objectively tested using our brake feel analysis solution, which incorporates brake robots fitted to the subject vehicle together with control and analysis software. In the following example, the test vehicle is a popular European EV and the test simulated the vehicle coming to a stop approaching a set of traffic lights. This involved an AB Dynamics RBR 600 model brake robot applying the brake to a specific position and holding the pedal constant, until the vehicle came to rest.

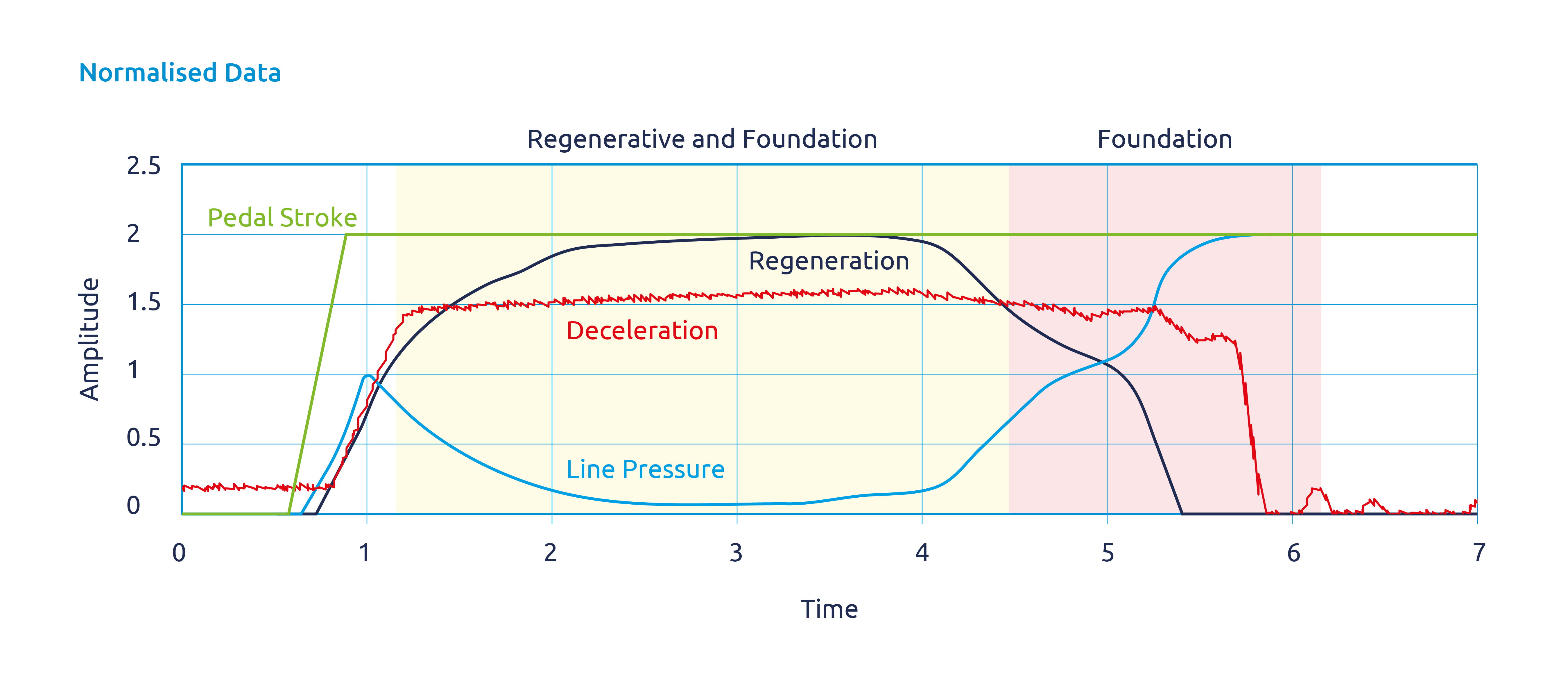

From this type of stop, the contribution of the regenerative and the foundation brake can be separated out and visualised (Figure 1).

In Figure 1, the deceleration begins to drop after four seconds. This is generally viewed as a negative characteristic because the driver is required to compensate for the system’s shortfalls by increasing pedal input.

The rating for this type of stop is a relatively low value, which is expected from this level of deceleration reduction during a stop.

This demonstrates that the vehicle has poor brake feel (5.5 on the AB Dynamics brake rating index, see part 1) in this scenario as the deceleration reduces despite a constant brake demand. To compensate, the driver must respond by applying more brake stroke. This type of brake characteristic reduces the driver’s level of confidence in the braking system and might even increase the likelihood of low-speed collisions as the driver underestimates the pedal stroke required to stop in time. This is a common issue with EVs as the regenerative braking torque reduces at lower speeds so the foundation brake needs to compensate. If the system fails to do this adequately it will require input from the driver.

Regenerative braking systems are significantly more complex than traditional setups. The development of these systems is still evolving as the technology advances. To accelerate the development, engineers would benefit greatly from a tool that can test, analyse, and evaluate them accurately and repeatably providing valuable objective data.

The AB Dynamics brake robots that are used as part of the brake feel analysis solution provide a level of control to the brake pedal that is beyond that of any driver, with levels of precision that have not been possible before. The repeatable inputs from the brake robots enable the braking system’s performance to be accurately measured, taking into account a reduction in the battery state of charge or a modification in the blending algorithm.

Our solution bridges the gap between objective and subjective evaluation, allowing the user to quickly understand the subjective impact of the braking system providing a visualisation of each braking characteristic and a subjective score. Importantly, this information provides quantitative information that can be shared within and across teams, providing the basis for objective decision-making.

This information will be critical in ensuring that brake feel and performance are to a level expected by consumers, leading to better satisfaction and reduced warranty issues.

Key takeaways

- Hybrid braking systems are complex and challenging to optimise, as they depend on multiple variables such as battery state, friction level, and driving conditions.

- AB Dynamics has developed a solution to objectively test and analyse the brake feel of hybrid vehicles.

- This solution enables engineers to optimise the brake controller, benchmark competitor systems, and validate brake system performance using objective data and subjective feedback.

- A working example of the solution applied to a popular European EV, demonstrates how the contribution of the regenerative and the foundation brake can be separated out and visualised, and how the brake feel rating can be calculated and interpreted.